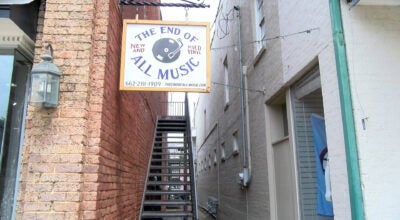

Cooper Tire ‘Dream Team’ visits Ole Miss

Published 2:00 am Sunday, February 26, 2017

- Representatives from Cooper Tire Company of Tupelo meet with Uuniversity of Mississippi Center for Manufacturing Excellence administrators and staff Wednesday, February 15, 2017. for a brief visit. Those meeting are front, from left, Scott Kilpatrick, Ross Blare, Jessica Synar, Nicole Williams, Robert Haggerty, and back, from left, Ryan Miller, Tyler Biggs, Josh Lavanway, Matthew Fulmer and Randy Moore.

By Edwin Smith

University of Mississippi

Expanding upon an already solid relationship with the University of Mississippi, the Cooper Tire & Rubber Co. “Dream Team” visited the university’s Haley Barbour Center for Manufacturing Excellence on Wednesday, Feb. 15.

Led by plant manager Robert Haggerty, six rising, early-career employees from the manufacturing firm’s Tupelo facility met with CME administrators and School of Engineering faculty members for an extended discussion and tour of the center. The Cooper group donated a sectional tire display, which shows the various layers of an SUV tire manufactured at the company’s Arkansas plant.

“Cooper Tire is a leading manufacturer with deep roots in Mississippi,” said Scott Kilpatrick, CME associate director of internal operations. “This concept certainly aligns with the mission of the CME in providing support to new and existing manufacturers in our state.

“This display will be important in demonstrating not only Cooper Tire makes their products, but it will also remind out students that there are exciting career paths available through the manufacturing sector right here in Mississippi.”

The “Dream Team” is a group of employees who visit middle schools, high schools, colleges and universities to inform students of career opportunities in manufacturing and with Cooper, Haggerty said.

Ole Miss chemical engineering alumni Nicole Williams, a Master SigmaSix Blackbelt; and Jessica Sinak, tire engineer; are on the team. Other members include Randy Moore, liability lead; Ross Blare, wire assembly utility; Josh Lavanway, VMI MAXX operator; and Matthew Fulmer, mechanical engineer.

“Through the ‘Dream Team,’ Cooper wants to show bright young students that they can find rewarding manufacturing opportunities right here in Mississippi,” Haggerty said. “Through automation in daily operations, we’re improving both the quality and increasing the quantity of tires we make.”

Sinak and Williams briefly explained the tire manufacturing process.

“Operators load raw materials into a mixing machine,” Sinak said. “Once the machine mixes the materials into rubber, it goes on to materials preparation, where the various tire components are made.”

The components go from material preparation into the VMI MAXX equipment.

“Inside the VMI MAXX, robots assemble the components into what we call a ‘green tire,” Williams said. “The green tires then go into a curing process where they are heated. Once they are done, the tires go to the finishing process.”

The VMI MAXX can assemble all the components into a “green” tire in seconds, Haggerty said.

“Each and every tire is placed on a test wheel, inspected and quality-checked before it is sent off to our warehouses,” he said. “Our goal is to build the best tire we possibly can in the fastest manner possible.”

The company’s longevity and the consistent quality of its products are cause for celebration, said Ryan Mille, CME associate director.

“Manufacturing, such as occurs at Cooper, has been ongoing in Mississippi for a long, long time,” Miller said. “The University of Mississippi School of Engineering and the Haley Barbour Center for Manufacturing Excellence certainly want to continue contributing to the state’s economic growth by producing graduates who find stable jobs within the state of Mississippi.”